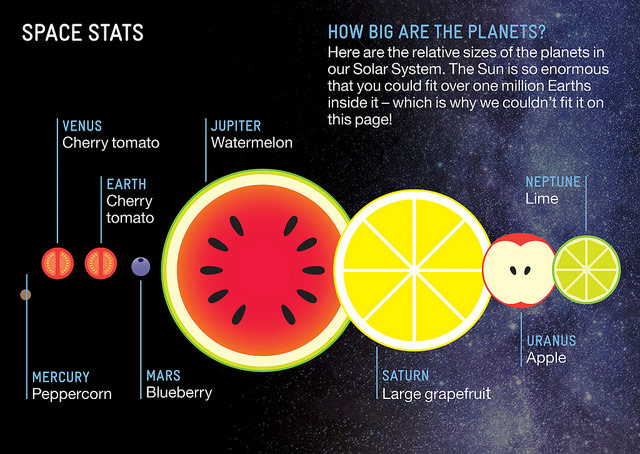

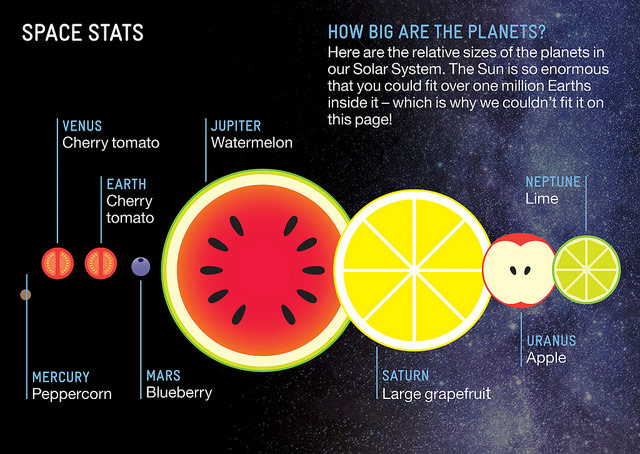

This is a great way to think about how big the planets of our solar system are: in terms of fruits.

(via boing boing)

Tags: astronomy food science spaceThis is a great way to think about how big the planets of our solar system are: in terms of fruits.

(via boing boing)

Tags: astronomy food science space

When it comes to building microscopic devices, one of the most promising ideas is to exploit the process of self-assembly. In this way, complex structures can be created by combining building blocks under natural circumstances.

This kind of self-assembly mechanism dominates at the molecular scale, where it is responsible for the construction of most biomolecules. At the heart of this mechanism is Brownian motion which effectively mixes and jiggles molecules so that they rapidly find their place in incipient structures. This is a powerful process that can form hugely complex machines such as the ribosome, a molecular device for synthesizing proteins.

One recent idea is to use colloids rather than molecules as the building blocks for even more advanced structures. Colloids are insoluble, nanometre-scale particles mixed in water. These particles can be chemically engineered to bind together to form specific structures.

But as the building blocks become bigger, it takes longer for Brownian motion to jiggle the blocks into the appropriate locations. So self-assembly take significantly longer. In fact, it can take thousands of seconds to synthesise a single colloidal molecule. At that rate, a millimetre cube containing 1 billion colloidal molecules would take 30 years to form.

Clearly, that is far too slow for any kind of industrial process, so chemists have been looking for ways to speed up colloidal self-assembly. Today, Bingqing Shen at ESPCI (the Paris Institute of Technology) in France and a few buddies say they’ve found an entirely new way to assemble structures on this scale that should reduce manufacturing time by orders of magnitude.

The new approach is to place the particles in a fluid flow and see whether this helps them assemble. The particles they want to assemble are tiny droplets of fluorinated oil placed in water. These droplets are 50 micrometres in diameter, about the width of a human hair.

The team injects a number of these droplets in a row into a flow of water that passes through a microfluidic chamber. It is easy to imagine that when the flow of liquid is steady and smooth, the droplets simply follow each other in line.

But Shen and co have observed something entirely different. As the droplets move through the chamber, they begin to assemble into specific shapes that depend on the number and types of particles involved but not on the detail of the initial conditions. Consequently, these shapes are entirely reproducible.

By injecting droplets with different compositions in various sequences, the team has produced all kinds of shapes including pyramids, tetrahedrons and even a three-dimensional spiral structure using magnetic drops in a magnetic field.

This kind of behaviour raises an interesting question. Given that the fluid flow is smooth, what causes the droplets to assemble in this way? “The self-assembly process is not driven by Brownian fluctuations because it would take days, while only a few seconds suffice in the experiments,” they say.

Instead, Shen and co think an entirely new hydrodynamic effect is at work. Their key discovery is that the self-assembling process works when the walls of the chamber are relatively close together but stops when the walls are moved further away. “We propose here that the physical origin of the phenomenon is linked to the presence of the top and bottom walls of the self-assembly channel,” they say.

In other words, the walls must be close to enough to interact with the droplets, slowing them down. This creates local changes in pressure in the fluid around the droplets that causes them to coalesce and tumble. It is this movement that allows them to self-assemble.

Crucially, this process is orders of magnitude faster than with Brownian motion. And because it is possible to produce the structures in parallel using many self-assembling chambers at the same time, this could dramatically increase the rate at which these kinds of materials are manufactured. “In our case, producing 1 billion structures in a one thousandfold parallelized device would take 30 days instead of 30 years,” say Shen and co.

Of course, this is still a long time but the team says there is considerable room for improvement. For example, they hope to significantly increase the flow speeds through the self-assembly chambers and they should be able to increase the parallelisation using tinier droplets and smaller mixing chambers. In this way, Shen and co say production rates could be increased by orders of magnitude. “Down the road, production rates of millions of clusters per second can be envisioned,” they say.

Having made these clusters, the final step is to assemble them into a solid material, which is done by drying them, possibly in the presence of an electric or magnetic field to align the clusters appropriately.

Shen and co say that it should be possible to change the droplet chemistry in such a way to manipulate the physical properties of the bulk material in ways that are currently difficult or impossible to do. This includes changing the refractive index, the electrical conductivity, the magnetic susceptibility and so on.

What these guys are proposing is an entirely new form of manufacturing based on clever chemistry and the powerful technique of self-assembly. Just where this will lead is not yet clear but it will be interesting to watch nonetheless.

Ref: arxiv.org/abs/1409.4009 Self-Assembly Driven By Hydrodynamic Interactions In Microfluidic Devices

There are several great replies here thus far. However, I believe something else needs to be considered - the nature of the consciousness created.

Data has a positronic brain. This implies something fundamentally different than the "conventional" quadritronic processing done in Starfleet computers. The fact that the "quad" and its various metric system designations (e.g. kiloquad) seems to amorphously float between a measure of memory storage and processing power doesn't help explain what the difference is one bit, but then, neither does the designation "positronic brain," which is what's used to describe Data's brain.

I think, however, that the best way to describe Data would be more along the lines of Data being more hardware-bound in many ways. That is to say, that Data's core brain is physically more similar to an organic brain than a computer. While it is not a pile of goo with neurons and synapses, it is probably akin to morphware, which is basically hardware that reconfigures itself like software.

The Doctor and other holographic systems rely on much larger and more powerful, conventional computer systems. This may well mean that these holograms have a rather different form of consciousness and sentience, in that they are essentially "simulated persons." Philosophically this may mean that they are "less" than people, or don't have true consciousness at all, but the audience generally assumes that at least the EMH is sentient. Nevertheless, if this is indeed the case, chances are there are differences that are at least oriented towards their subjective qualia, leaving Data's "experience" to be much more like that of a conventional organic being, yet with the advantages of a computer.

However, we should not be quite so hasty in judging just what the Doctor is. The Doctor's computer systems were unique on Voyager. In one early episode it was stated that it would be impractical for him to be transferred off the ship and out of the sickbay systems (Voyager episode Life Support). This implies some sort of specialized hardware, since otherwise he could be brought, if need be, in a few suitcases of isolinear chips. Let us ignore for the moment that he'd almost certainly have ended up vivisected (or decompiled, or whatever the equivalent is for holograms) by the Romulans for his technology in that particular case.

Another thing that suggests possibly specialized hardware for the Doctor is the fact that the mobile emitter CAN apparently separate the Doctor from Voyager entirely. Furthermore, it does so in a rather illogical manner from a computer science perspective, specifically that the Doctor seems to cease to exist in the Voyager computer, as opposed to a copy being created. Whether this can be a comment on the technology backing him, or an example of the writers ignoring or being ignorant of computer mechanics, is difficult to determine, and I'm pretty sure it was never addressed. Looking to the mobile emitter is of little use. I'll bet the Federation can copy it and repair it, but it will be a considerable time yet before they understand it. Nevertheless, this does show that it's possible that the Doctor uses more than conventional computing power to attain sentience and consciousness. He may well use some sort of (until the mobile emitter, unmovable) Data-like brain for at least part of his program. However, that doesn't mean that there's a giant copy of Data's brain behind one of the walls in sick bay; this could just mean that he's got a processor in there somewhere that takes care of a certain portion of his cognition with most of the actual processing being in conventional computer systems.

Nevertheless, since it seems (to me, at least) that the evidence weighs in that sentient holograms are still running MOSTLY on conventional technology, this leaves Data rather unique. Even if the holographic AI allows Starfleet to produce new, intelligent beings, the process by which the sentience occurs is still different from the way it does in a person, which has scientific value on its own, and may have functional value that is not obvious. It is also noteworthy that this would have some objective consequences as well as subjective consequences. While we are not equipped, as an audience, to determine these, as we know little about the technology, a major one comes in the form of actual programming. It is possible that Data's "programming" is considerably different than what would normally be considered programming. Furthermore, he seems to be resistant to external programming attempts, considering his confidence in the face of Borg coercion. The EMH, on the other hand, is modified as a program several different time during the series, and is also subject to "orders" from the holodeck program he's in, such as falling under hypnosis because the program says so (Voyager episode Spirit Folk). Whether or not the crystalization of a structure producing consciousness is a criteria for considering it to be actual or merely emulated consciousness is a decision for the Federation courts, I suppose.

So in short, one major thing that renders Data unique is HOW he is made into a sentient and conscious being, and that it is probably in a manner much more similar to organic brains than what would be produced by a hologram.

Now, THAT mouthful out of the way, I have to agree with other posted assessments in many ways. Remember that Data's been around and operating for several decades and has probably been poked in just about every part of him in one way or another. It's not impossible that they've figured out a lot of how he works. In fact, Data himself volunteered for some of Dr. Maddox's experiments once he was sure it wasn't going to kill him in the process (TNG episode Data's Day). It's not unthinkable that Maddox indeed perfected the experimental technique, ran it on Data harmlessly, and managed to come up with a way to replicate positronic brains. Further, we have at least two instances where positronic cognitive hardware were introduced in the series. Lal, first and foremost, produced a complete, if unstable, positronic brain, that in fact lived for several days (TNG Episode Lal). However, another thing that suggests that positronics are considerably more advanced is what happened with Vedek Bareil (DS9 Episode Life Support). He had half his brain replaced with positronic equipment, and although it made him something of a technozombie, he was nevertheless still a conscious being. And Bashir implied that he could do it for the rest of his brain, though refused since Bareil really would be a technozombie if he did it. Although it could be retconned back that the only reason Bashir could do this was because he was a super genius, it seems like it's a bit of a stretch, especially considering it would be almost impossible to cover up that he managed to cook up this plan all on his own on the fly even though the best engineers in the Federation had been slowly piecing together the puzzle of just how it worked for decades, let alone deliver a fully functional medical application.

Furthermore, as in the extracanonical material, Data was revived in B4, it is likely that reverse engineering of that extent was revolutionary in the understanding of the positronic brain. With this in mind it is possible that Data's resurrection may have simultaneously answered many of the questions that remained. Plus, if I recall correctly, Data basically "promised" B4 that he'd make him a new brain as B4 was essentially reversibly replaced with Data's mind. This gives Data a VERY direct reason to find out a way to make a new brain - both to give his brother a new positronic brain to exist in, as well as try to help him overcome any limitations of the hardware that Data can likely bypass due to superior programming, but B4 may be restricted by.

So in short for THAT text blob, most of the references to Data's uniqueness were in TNG, and furthermore we saw at least two examples of technology's progress making that uniqueness a far shakier prospect.

Aug. 26, 2014 | By Alec

In Minnesota, contractor Andrey Rudenko is currently working on a project of gargantuan proportions that seems to be stretching and exploring the limits of 3D printing technology. Using a printer that was substantially modified and expanded, he has printed a concrete castle in his own backyard. And at 3 by 5 meters, this concrete structure is the world's first 3D printed concrete castle, and one of the largest objects that has, up till now, ever printed with 3D printing technology.

Rather than trying to build a machine that caters to theme parks and history enthusiasts, this project grew out of a desire to construct a 3D printer capable of constructing durable, realistic and inhabitable houses. He's already looking at various locations to realize this: 'last winter in Minnesota, which was long and frigid, showed that it is crucial to have multiple areas in different countries for experimental printing since you can never predict which conditions will arise.'

But Rudenko, who has a background in engineering and architecture, chose to firstly print his fantastical castle. This allows its creator to search for and experiment with the limits and possibilities this machine offers to construction companies. The castle's unique features and shapes offers many challenging opportunities to do this, and leave room for Rudenko to make minor adjustments to the machine. And of course, it's also a wonderful showpiece for his huge 3D printer.

As Rudenko told <a href="http://3ders.org" rel="nofollow">3ders.org</a>, this project follows years of preparation and planning:

'I've been interested in this technology since I was in my teens. My concrete printing experiments started about 20 years ago, but at that point, advanced computers and software were not available for this type of technology. It wasn't until a couple years ago that I came across the RepRap project and started working on this machine again. It took about a year to build and develop special concrete mixes. Additional inspiration came from the naturally-laid layered sandstone I saw on a trip to Arizona a few years back. Ideally, I hope I can obtain the same natural look to my printed walls.'

Furthermore, progress was also hampered because of the finances involved. Rudenko therefore ended up financing the printer independently, which led to many creative engineering solutions.

'When I was starting out, potential sponsors were wary of providing funds since they did not think the technology would go this far. Once the castle structure is built and the capabilities of the printer are evident, I plan to conduct an auction of the ownership to the first house; since this will be the first functional 3D printed house ever built, I'm hoping there will be a lot of takers and this will become a valuable landmark.'

A project of this size obviously needs a printer of corresponding proportions, and Rudenko necessarily built his own machine. While he has received lots of very helpful feedback from the RepRap community, the actual construction was of his own design. This massive machine is driven by Arduino Mega 2560 board and software, which is not too different from some other 3D printers, but it requires special stepper drivers 'For a big printer, I need special drivers that can handle the heavy weight of the machine as well as be compatible with the software/firmware. The best fit I found was from James Newton's Mass Mind.'

'These drivers ended up being the only ones to work properly with Marlin Firmware (I sampled other drivers, which failed), and were powerful enough to move such a huge printer.' Rudenko added.

This printer is therefore slightly different than the one developed by Behrokh Khoshnevis at USC. 'Design-wise, I'm creating a natural, free-layering of fine concrete and my goal is to have a nice-looking, natural texture, without the need for any additional finish, similar to rammed earth technology.' Rudenko is also seeking to develop a portable machine that even smaller construction companies can afford. 'The final price will be known once we build a few houses, but to the best of my knowledge, I currently see it as being priced at $30,000-50,000, though this will also vary depending on the parts and type of model.'

When that time comes, Rudenko hopes to be able to deliver a number of different kits that individual customers and small companies can put together themselves. 'Obviously I can't ship the whole machine, but I can ship an extruder, control box, some major parts, etc to help individuals put together their own version.' Khoshnevis's printer, on the other hand, at least appears to be heavier and larger, and Rudenko expects that only large-scale construction companies will be able to afford it.

The building process of this 3D printed concrete castle is now complete, but it's also a learning process for Rudenko's future plans. He's currently printing approximately a layering of 50 centimeters per day, though the size and width of the layers vary throughout the construction. Regular layering is being printed at 30mm width by 10mm height, but Rudenko can print layers of virtually any size. 'For special areas like crown moldings, I am reducing the height to 5 mm; I'm also reducing speed in delicate arias.'

Of course, a construction of this size requires the right materials to sustain the sheer size and weight of the concrete.

Rudenko said, 'Layering cement was an extremely difficult task- it required extensive tuning of the printer on a programming level, as well as using exact quantities for the cement mix. While testing the printer, I ran into obstacles (such as the nightmare of the extruder clogging) and discovered even further abilities of the printer, like that it can print much more than 50cm a day as I originally thought.'

Rudenko therefore resorted to including rebars in the bottom and top walls. 'They are needed during the pouring of a variety of cementitious filling materials inside the printed walls.' The cement used, however, is just a regular cement mix with a few additives. 'It is possible to use a special quick-setting concrete to speed up the process, but it will affect the cost, and I don't see much reason to build a house extremely fast at the expense of higher cost and lower quality.'

Instead, Rudenko is after quality and new possibilities. 'The more important advances of this technology lie in its architectural possibilities and energy-efficiency. Architects have waited many years for this technology, and now that it's here, this opens up a whole window of possibilities; soon, we will see new kinds of architecture used to construct new structures.'

This Minnesotan constructor is seeking to a part of this: 'I plan to concentrate on the development of further 3D printing technology in construction and building a community/network of people worldwide interested in research and development of this technology, with the possibility of providing DYI kits as well as a full line of model construction printers.'

For now, however, printers that are suitable to construct homes and be commercially viable as well are still in the distant future. But Rudenko is optimistic about the possibilities for both his device as well as this industry. 'My current standard is 10 millimeters in height by 30 millimeters in width, but countless other options are available with just the click of a button.' he said.

Rudenko is in the process of redesigning the printer based on the lessons learned. His goal will be to have an upgraded printer that prints 24 hours a day until the project is finished.

'I'm also planning to print the structure in one piece; printing the castle turrets by themselves was a bad idea as they were extremely difficult to lift and place. Additionally, I've figured out how to print a roof; the only thing is that the material I'd print with would have to be used in warmer climates for now.'

Rudenko's next project is a real full-scale livable house. 'The amount of correspondence I am getting proves high demand and interest in this new technology. I want to make sure that for the next project, I have the right team doing the job to fully use all of the benefits of the 3D printing machine.'

'I am open to offers from individuals or companies interested in owning the first house of this type built with the newest 3D printing technology and ready to provide abundant funds to completely cover the project and all its expenses. The interested party needs to own the lot/site and possess a permit for a house built by 3D Printing technology.' Rudenko would also like to collaborate with the interested architects, designers, and software engineers experienced in 3D tools. And you can contact him via this email for further questions.

It has been two years since Rudenko first began toying with the idea of a 3D printer that was capable of constructing homes. 'I have previously been sure I could print homes, but having finished the castle, I now have proof that the technology is ready.' Rudenko said.

'The current prototype I am working on at the moment is just a small part of the line of printers I am designing. We are talking about the beginning of a new era in construction industry. There is still much to be done.'

Watch a video of Andrey Rudenko's printing process here:

Posted in 3D Printing Applications

Maybe you also like:

alidan wrote at 8/28/2014 11:52:03 AM:

@Julio you could probably do something to get a paint scraper to do the work, but it would need to be an engineered process really what you could do is have an outside edge pre determined, and have something that would hold an outer layer of concrete on it to smooth that crap out. personally, i love the layerd look because i could fairly easily get some ivy to grow up it and make the whole thing covered in green.

Julio wrote at 8/27/2014 9:52:49 PM:

Adam, that's not possible. You would need to orient the scraper along the outer surface and in this design the extruder doesn't rotate. You would need an extra DoF. So not "hell, duct-tape the paint scraper to the print head". Think a little more.

Adam wrote at 8/27/2014 4:15:32 AM:

I think 3d printing concrete gets a bad rap because of the unfinished look of it, the ridges and all, but really you could just go over it with a $2 paint scraper and smooth out the outer walls and it would look completely legit and professional. hell, duct-tape the paint scraper to the printhead ( a few inches down) and the smoothing process is now automated. can't wait to print a castle of my own. one day you'll either have your own concrete printer, or rent it from the hardware store for a weekend like any other large tool.

Vindinium is an Artificial Intelligence programming challenge. You have to take the control of a legendary hero using the programming language of your choice. You will fight with other AI for a predetermined number of turns and the hero with the greatest amount of gold will win.

CreditSönke Johnsen/Duke University

Sönke Johnsen scuba dives in the middle of the ocean, far from land, miles above the seafloor. There are no shipwrecks to explore, no reefs to admire, just a disorienting oasis of blue.

What he looks for is hard to see. Indeed, he and his companions often stare intently at one another, searching for distortions passing among them, slightly more visible against the dark color of a wet suit. And then they carefully catch them and place them in glass jars.

“You’d be surrounded with all these animals,” said Dr. Johnsen, a professor of biology at Duke. “But you could barely see them, because they were transparent.”

The oceans, which make up more than 90 percent of the earth’s livable space, are full of almost invisible animals. That is because life there is different from everywhere else.

To illustrate why, Dr. Johnsen began a recent talk with a macabre scenario. Suppose just then a gunman burst into the room, shooting at the audience. Naturally, people would scramble for cover behind chairs and walls.

His point: There would be places to try to hide.

On land, many animals camouflage themselves amid the foliage and terrain; in coastal waters, sea creatures blend into the sand or find refuge among coral or rocks. But in the deep ocean, Dr. Johnsen’s realm of expertise, creatures floating in the water have nowhere to seek refuge from larger creatures that would eat them.

Sharks and whales can swim with impunity, but many other creatures need to hide in plain sight.

Transparency is the most obvious strategy — if light passes straight through, no one can see you — and the one Dr. Johnsen first began researching almost 20 years ago. In graduate school, he had been studying clear biological tissues like the lenses in eyes.

“I wanted to try to understand why they were clear,” he said. “What was the physics of that? What was the mathematics of that?”

By chance, his doctoral adviser mentioned that the open ocean was full of transparent animals. “Which was totally news to me,” he said.

He shifted his research focus from transparent tissues to transparent creatures, beginning with a postdoctoral fellowship with the marine biologist Edith Widder at the Harbor Branch Oceanographic Institute in Florida. Transparency is not just a lack of pigmentation. Albinos, Dr. Johnsen points out, are not invisible; rather, the entire body must absorb or scatter as little light as possible.

Scattering, in particular, is a challenge. When light passes into a material of a different index of refraction, which is often proportional to the density, part of the light reflects and part of it bends. That largely explains why one could search long and wide for a transparent cow or a transparent pigeon and not find one: The density of air is so much less than that of flesh that even a see-through terrestrial animal would probably be easily spotted from its reflections.

Water is much denser, and body tissues are roughly the density of water, greatly reducing the amount of scattering. But some organs are denser than others, and the transparent animals pack their insides differently to minimize the variations and the reflections.

“He did a lot of the theoretical mathematics to show what was needed to be transparent,” said Dr. Widder, now chief executive and a senior scientist at the Ocean Research and Conservation Association in Fort Pierce, Fla.

Dr. Johnsen’s measurements of the see-through creatures that he brought up found that 20 to 90 percent of the light passed through, undisturbed. “You could read a book through these animals,” he said.

An eel larva is almost flat, and its see-through body is almost featureless except for the bones. “These guys can actually absorb some of their nutrients through their skin, so I don’t think there’s much of a gut,” Dr. Johnsen said.

But transparency can complicate life in other ways. Transparent creatures near the surface could be sunburned, not only on the skin but inside, too. To protect themselves from ultraviolet light, “these guys basically have suntan lotion in their transparent tissues,” Dr. Johnsen said.

But that then allows predators with eyes sensitive to ultraviolet light to see them after all. “There’s this evolutionary arms race,” he said. “I call it ‘Fry or die.’ ”

The esoteric knowledge of deep-sea transparency could have practical applications. “A lot of what I learned about transparent animals, I then applied to human cataracts, which could ultimately help people out,” Dr. Johnsen said. Evolution has come up with two other forms of stealth technology: mirrors and little biological light bulbs.

Many predators find their food by looking for silhouettes above. “You see many animals with upward-looking eyes, and even a squid with one big eye looking up and a ‘normal’ eye looking to the side,” said Steven Haddock, a scientist at the Monterey Bay Aquarium Research Institute in Moss Landing, Calif.

The silvery sides of fish like herring and sardines are systems of mirrors: They reflect the downwelling light, much the way a part of the sky is sometimes reflected by a glass skyscraper and blends into the rest of the sky. Thus, a predator from below would see the blue water, not a fish, swimming above. “A tuna is exquisitely adapted for camouflage,” Dr. Johnsen said.

Eric Denton, a British marine biologist, studied mirrored fish in the 1960s and figured out that the mirrors were vertical, maximizing the illusion.

The third strategy, called counterillumination, also seeks to mimic the downwelling light. But instead of mirrors, the animal generates its own glow, much as fireflies do with light-producing organs known as photophores.

Dr. Haddock witnessed the effectiveness of counterillumination in a dimly lit laboratory with a midshipman fish swimming in a transparent tank. He lay beneath the tank and looked up at the fish, about two feet away. “I couldn’t see the fish against the background when it turned on its special belly lights,” he said.

The different creatures employing counterillumination also make sure the light they are producing is pointed downward.

“They don’t want light leaking out to the side and making them vulnerable, so they have lenses, mirrors and filters on their photophores,” Dr. Haddock said.

The cookie cutter shark also employs counterillumination, to more ferocious effect. Tiny light-producing organs provide perfect camouflage. “Then it screws it up with this black band behind its jaw,” Dr. Widder said.

She suggested that the black band was a lure, looking like a small fish that a tuna would like to eat. When a tuna closed in, the shark swiveled around and ripped a chunk of flesh from the fish. That solved the mystery of how this slow-swimming, small shark — only about two feet long — was able to get a bite of a larger, faster tuna.

Some creatures use more than one form of camouflage. For one thing, it is impossible to be entirely transparent. Certain tissues, like retinas, need to absorb light to function. The otherwise transparent squid Chiroteuthis has a light organ to hide its large, opaque eyes, Dr. Haddock said, adding, “The whole eye tilts as the squid swims up and down to keep the light pointing downward.”

A transparent squid also has an opaque gut, because what it eats often is opaque or, worse, glows, which would attract the attention of a larger predator. To minimize its visibility to predators swimming below, the squid’s gut is long and thin, like a needle, and swivels so it points vertically.

The gut itself can have mirrors as supplemental camouflage. Some creatures have evolved ways to defeat the camouflage. Species of squid and shrimp have eyes that can differentiate between the two polarizations of light, something that many insects can do, but which people and most other land creatures cannot do without polarized sunglasses.

Photons — particles of light — can be thought of as arrows with tail fins representing the oscillating magnetic and electric fields, and the polarization represents the orientation of the fields. To human eyes, the color of reflected light is unchanged. When reflected, the angle of the polarization changes.

As the sun moves across the sky, the polarization of light filtering down to the depths changes, and to an eye that can tell the difference between the polarizations, a mirrored fish suddenly sticks out like a sore thumb.

“It turns out while the camouflage is really good, you can really break it with polarization vision,” Dr. Johnsen said.

That might, for instance, allow a squid to spot an approaching hungry tuna and flee.

Much remains to be learned about what lives in the oceans.

“We’re catching the small, the slow and the stupid, because anything else just goes away,” Dr. Johnsen said. “We’re just surrounded by an entirely mysterious world.

“And the fact we can’t see it means we ignore it most of the time.”